TECHNOLOGY

PNEUMATIC VALVE & ROD (PVAR) SYSTEM

Conventional or standard parts such as the gas block, gas tube, handguard, bolt assembly, the bolt carrier, polymer handguard and barrel lock, among others, were replaced with UDMC’s proprietary patented Pneumatic Valve and Rod (PVAR) System. Specifically, instead of the hollow gas key, it was replaced with a one piece bolt carrier with a solid “punch key” where the piston rod communicates or transfers the mechanical energy by pushing the bolt carrier rearwards for a much more reliable cycling.

The UDMC PVAR System executes the replacement of the operating assembly of the conventional AR, M16, M4 and similar rifles. Where in the Direct Gas Impingement System gas is used throughout the operating cycle, the UDMC PVAR System utilizes mechanical energy instead for a more effective and more reliable cycling.

The UDMC PVAR System prevents much of the heat, carbon build-up, unburned powder, and dirt from being deposited inside the bolt assembly and the bolt carrier group resulting in a cleaner and cooler operation, less downtime for cleaning and repair and considerably longer life span of the rifle.

Reduced Field Maintenance

The PVAR system eliminates the constant cleaning requirements of the AR, M16, M4 and similar rifles in the field. Where the conventional design requires general cleaning of the operating parts every so often, the PVAR rifle requires minimal cleaning (or just check-up) of up to 2,000 rounds, certainly much more volume of fire in between cleanings if compared with conventional direct gas-operated rifles. The PVAR valve, piston rod and spring can be removed from the front of the gas block without special tools and without dismantling the whole upper assembly!

Reduced Wear and Tear and Extended Rifle Lifespan

The PVAR system eliminates the constant cleaning requirements of the AR, M16, M4 and similar rifles in the field. Where the conventional design requires general cleaning of the operating parts every so often, the PVAR rifle requires minimal cleaning (or just check-up) of up to 2,000 rounds, certainly much more volume of fire in between cleanings if compared with conventional direct gas-operated rifles. The PVAR valve, piston rod and spring can be removed from the front of the gas block without special tools and without dismantling the whole upper assembly!

Reduced Rate of Fire

The PVAR Rifle has a reduced rate of fire (750 rounds average per minute). This slower rate of fire and the “cancellation” of the excessive rearward pressure (found in DGIS rifle) is eliminated via the PVAR’s forward and backward mechanical movement of the piston rod thus resulting to operating cycle reliability, less recoil, less muzzle rise and excellent firing accuracy of the rifle in the hands of even a newly-recruited light-to-medium framed soldier, regardless if the barrel rifling twist is 1×7, 1X9 or 1×12, and regardless if the ammunition used is 55 grains (M193) or 62 grains (M855).

In other words, the PVAR design has greater flexibility, reliability and accuracy than the conventional gas-tube designs and even in comparison with the other gas-piston generic designs from other countries that are being sold supposedly as “drop-in” kits which, do not function reliably particularly on bursts and full automatic modes, but in which modes the PVAR rifle is guaranteed to perform!

Easier Takedown and Assembly

The PVAR system can be easily removed from the front of the gas block, taken-apart, cleaned, and reassembled in the field in a matter of seconds, unlike the conventional gas-tube and other gas-piston designs which require the removal of the handguard with special tools for proper dismantling and cleaning or replacement of parts and which will take several minutes to dismantle and re-assemble.

Currently, the UDMC Pneumatic Valve and Rod (PVAR) System is available in variants of the M16 and M4 in caliber 5.56 NATO with barrel lengths, from the 7.5 PDW up to the 22 inches sniper model and any length in between. The PVAR rifles are also available in variants of the M110 in caliber 7.62 NATO, from the CSASS length of 14.5 inches up to the sniper model of 25 inches.

Optimum Flexibility and Improved Accuracy Through a Floating Barrel Design

The PVAR rifle was designed with enhanced accuracy in mind through our proprietary (part of the patents) one-piece quadrail handguard with military-specs picatinny rails mounted on a round barrel lock cum handguard mount. The one-piece quadrail handguard enables a true “floating-barrel” that greatly aids in the consistency and accuracy of the fired round since the handguard was designed not to touch any part of the barrel at any point along the barrel’s length except at the barrel extension.

The barrel is mated to the rifle’s upper receiver through the barrel lock which also holds the handguard securely in place such that the barrel now “floats freely” without any contact with other rifle parts other than the rifle’s barrel extension which is securely attached by the barrel lock to the upper receiver near the chamber. This minimizes mechanical pressure, distortion, and vibration throughout the length of the barrel when a round is fired.

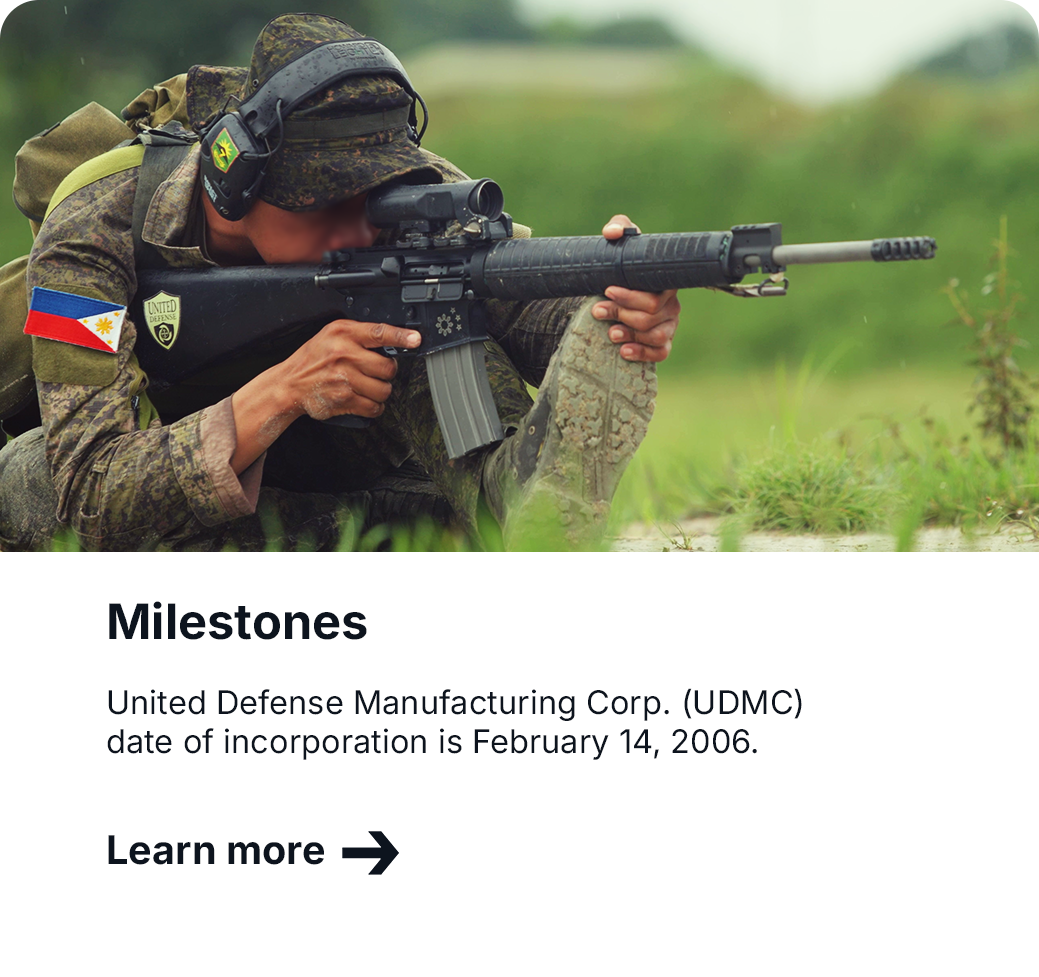

Reliability Under Adverse Battle Conditions

The PVAR Rifle has been proven to fire reliably even with sand, mud and water inside its system. A perfect weapon for SEAL and SF operations.